Contract Manufacturing

Our team brings experience from the fine chemical, pharma and biotech industries and can help you at any stage in your development process. Our style is highly collaborative, emphasizing close contact, open communication and full disclosure of progress – both accomplishments and roadblocks/issues, to enable rapid decision making and project success.

Apertus capabilities include:

- Development and/or manufacture of capsule, tablet, cream, liquid and suppository products.

- Apertus is registered as a Manufacturing and Analytical facility

- Currently manufacture prescription tablet, capsule and suppository products

- Can also manufacture OTC or cosmetic products

- Device manufacturing

- Apertus is registered as a Device facility

- VAI in the FDA facility database (2020)

- Release testing for raws and finished goods performed in-house.

- Co-development and validation of HPLC methods along with formulations.

- Can manufacture custom suppository shells at our Saint Louis facility.

- Serialization of carton-packaged products in-house.

- Registered with the DEA (Schedule II-V)

- Currently have Analytical and R&D registrations

- Prior Manufacturing registration (I-V) can be renewed on customer request

Current Equipment:

- Ribbon blender: 5 cubic foot ~ 50kg batches

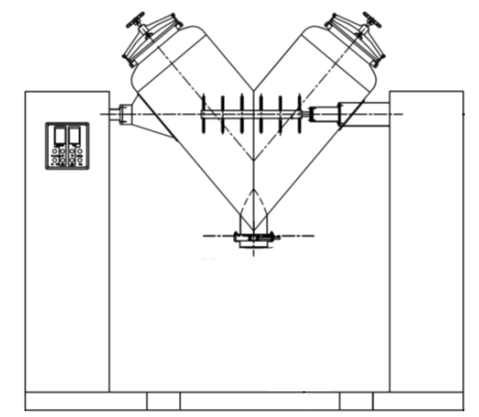

- V-Shell blender with intensifier bar: 10 cubic foot

- Manesty Beta Presses (2): 16 station; ~60,000 tabs/hr

- Semi-auto encapsulator (~25,000 caps/hr)

- Two Suppository manufacturing lines (~6000 doses/hr)

- Optel Carton Serialization & Aggregation Workstation

- Semi-auto ABL tube filler and sealer

- 80 Gallon jacketed blend tanks (2)

- Semi-auto liquid bottle filling, capping and sealing line

- Full-auto encapsulator (50,000 doses/hr)

- Suppository shell printing and forming line (~12,000 shells/hr)